Elevator features and product patents -

Features of Fuji elevator integrated controller:

● The integrated design of elevator drive and control makes the control structure compact and better performance, the system assembly wiring is simple,

reduces external wiring, and reliability is increased.

● Direct parking technology based on the principle of distance control, directly decelerates to the leveling position without the final speed running section.

● In the acceleration section of the elevator, it immediately responds to car interception, shortens the running time and improves the transportation

efficiency.

N speed curves are generated instantly, and the best operating efficiency and sense of ride can be achieved without being restricted by short floors.

● Multi-CPU redundant control improves the immediate control ability and safety of the elevator. The elevator control and drive control have complete safety

protection capabilities, which greatly improves the safety factor of the elevator.

● Integrate advanced CANBUS, MODBUS, GSM and other communication technologies to improve data transmission capabilities.

● Built-in accurate real-time clock, providing time-sharing control function, fault occurrence time and running time record query, convenient for maintenance

operations.

● Built-in more than 60 fault detections, fault level classification processing, and comprehensive record of fault messages, Storing multiple fault messages and

time can save the time for determining the cause of the fault to speed up troubleshooting, and implement individual protection measures according to the

severity of the fault.

● The use of load-compensated start-up technology with no-load sensor enables the elevator car to have excellent start-up comfort without installing

weighing devices.

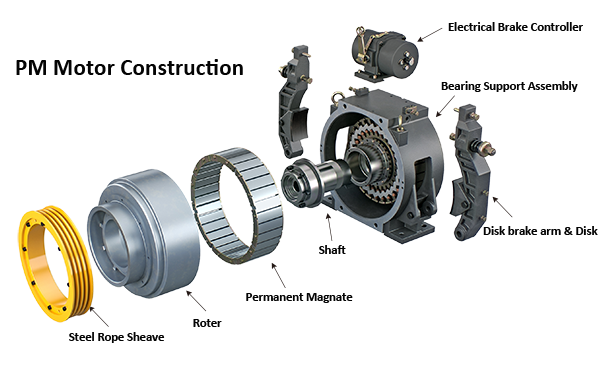

The Benefit of PM Motor:

It is the abbreviation of gearless permanent magnet synchronous motor. Compared with the combination of traditional induction motor and reduction gear box, its volume is much smaller, and its high efficiency operation will be relatively energy-saving than the traditional motor. And environmentally friendly.

Permanent magnet synchronous motor replaces AC induction motor. Because it transmits torque through non-contact electromagnetic force, it solves the problem of jitter in the startup and operation of general traditional elevators, making elevators run more smoothly and more comfortably, while reducing the size of the motor. The noise is reduced, especially its energy-saving effect is very significant. If a gearless traction machine is used, when the brake of the elevator fails, the current braking function of the permanent magnet synchronous motor can be used to ensure the low-speed sliding of the car to avoid accidents, which is safe for the elevator. Add a safety barrier.

"Energy-saving" and "environmental protection" have become the clear themes of current industrial products. The current elevator design is the most different from the previous elevators, which is driven by PM permanent magnet synchronous motors. Gear traction machine greatly improves the efficiency of operation.

Product Patent - Anti-burst protection device for elevator permanent magnet synchronous motor

Republic of China Patent Certificate Invention No. M1657654

Anti-burst protection device for elevator permanent magnet synchronous motor

When the elevator is in automatic operation and the motor decelerates to stop and open the door, if the brake that relies on the brake motor fails, the star-closing circuit is delayed by 1 to 2 seconds, the car may have moved 3 to 9 meters quickly, and it is difficult to guarantee the elevator. No personnel accidents occur.

Moreover, the life of the capacitor is aging year by year due to the influence of time and ambient temperature, and the quality is difficult to ensure.

In order to overcome the above technical defects in the industry, the company invested in R & D and improvement to replace traditional power resistors with NTC resistors.

Because the resistance value of NTC at normal temperature is large, the instantaneous high current at the time of star star short circuit is suppressed at high speed of the synchronous motor, and the NTC becomes extremely low resistance after heating, so that the synchronous motor has a large braking torque when stopped , Reduce the speed of elevator sliding, greatly improve the comfort and safety of passengers.。

product patents - Low-noise elevator brake control device

Republic of China Patent Certificate Invention No. M564035

Low-noise elevator brake control device

The main noise sources of the elevator are the hoist motor, reduction gear, electromagnetic brake of the brake motor and electromagnetic contactor that controls the power of the motor in the machine room. The advantages of this product are as follows:

(1) Apply silicon controlled gate fluid and time control circuit to control voltage.

(2) The action of the brake after the power is turned off is gentle, which reduces the

collision sound of the brake pad and the brake drum.

(3) The relay is a hermetic package type, and the contact is not easily oxidized with time.

Because it is used for zero-point voltage control, there is no current when the contact

is opened and closed, so there is no spark, and the contact life is long, It is explosion-

proof and prevents electromagnetic interference to surrounding electronic products.。

(4) The power supply end has slow blow fuses, noise filter capacitors, lightning surge

protector and rectifier.

(5) With over-current short-circuit protection circuit, the output is automatically cut off

when the instantaneous current exceeds, to avoid contact adhesion and damage of

electronic parts.

(6) With output feedback detection circuit, the elevator control system can be notified by

the feedback signal to make the product more safe.

(7) The operating voltage of the special control terminal can prevent the coil from being

burned or the contactor iron core to vibrate, buzz, bounce and spark when the voltage

is wrong or the frequency is unstable.

(8) The primary power supply at the control end adopts RC resistor-capacitor step-down

circuit and has lightning strike protector and resettable fuse. The RC step-down circuit

is simple and reliable, and can withstand the frequent start-up operation of the

elevator.

(9) The circuit board of the elevator machine room is coated with insulating paint for

dustproof and moisture-proof treatment, and then applied with a metal cover for

protection. The average life can reach more than several times of the general

components in the industry.

product patents - Clamp protection device for accidental movement of carriage UCMP

Republic of China Patent Certificate Invention No. M561081

Clamp protection device for accidental movement of carriage UCMP

Unintended Car Movement Protection (UCMP), derived from the European amendment EN81-1: 1998 A3 amendment: when the elevator is in the leveling position and the door is open, if the elevator moves unexpectedly, UCMP safety Immediately start protection and stop elevator operation, adding a safety guarantee for passengers. UCMP is aimed at motors and control systems, and can be divided into detection devices, control circuits, and brake components.

For detailed regulations and explanatory documents, please contact the company's business staff for request.